A shunt motor is a type of DC motor where the field winding is connected in parallel or shunt with the armature winding. This means that the same voltage is applied to both the armature and field windings.

Construction of shunt motor:

- Frame: The frame of the motor is usually made of cast iron or steel and is designed to provide support for the other components of the motor.

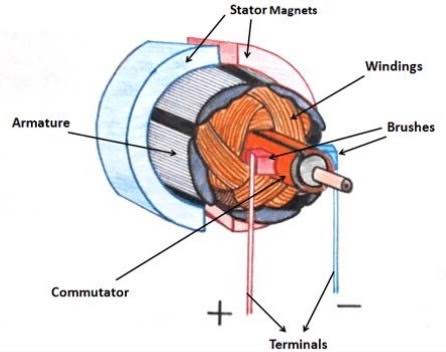

- Armature: The armature is the rotating part of the motor and is made up of a cylindrical core with slots for winding copper wire. The armature is mounted on a shaft and rotates within the field produced by the stator.

- Field winding: The field winding consists of coils of wire that produce a magnetic field when current is passed through them. In a shunt motor, the field winding is connected in parallel with the armature.

- Commutator: The commutator is a ring of copper segments mounted on the armature shaft that connects the armature windings to the external circuit. As the armature rotates, the commutator segments make contact with brushes that transfer current to the armature windings.

- Brushes: The brushes are made of carbon or graphite and are mounted in brush holders that ride on the commutator. The brushes transfer current to the armature windings as the commutator rotates.

- End caps: The end caps are attached to the frame and provide support for the bearings that support the armature shaft.

- Bearings: The bearings are used to support the armature shaft and reduce friction between the moving parts of the motor.

- Terminal box: The terminal box is mounted on the frame and provides a connection point for the external circuit.

Working of shunt motor:

When a voltage is applied to the armature, a magnetic field is generated in the field winding, which interacts with the armature’s magnetic field. This causes the armature to rotate, generating mechanical power. The shunt motor’s speed is proportional to the voltage applied to the armature and inversely proportional to the armature’s resistance.

Types of shunt motor:

There are two types of shunt motors:

- Cumulative Compound Motor: The field windings of the cumulative compound motor are connected in series with the armature winding, which increases the motor’s torque. This makes it suitable for applications that require high starting torque.

- Differential Compound Motor: The field windings of the differential compound motor are connected in opposition to the armature winding, which reduces the motor’s torque. This type of motor is used for applications where constant speed is required, such as in machine tools.

Advantages:

- Shunt motors have good speed regulation and can maintain a relatively constant speed under varying loads.

- They have good starting torque and can be used for applications that require high starting torque.

- Shunt motors are easy to control and can be easily controlled by varying the applied voltage.

Disadvantages:

- Shunt motors can be expensive compared to other types of motors.

- They can draw excessive current if the load is too high, which can lead to overheating.

- They can produce sparks at the brushes, which can cause electrical interference and create a fire hazard.

Applications

- Machine tools: Shunt motors are often used in machine tools such as lathes, milling machines, and grinders. They are able to provide precise control of speed and torque, making them ideal for these types of applications.

- Elevators and hoists: Shunt motors are also commonly used in elevators and hoists. They are able to provide the high torque required to lift heavy loads, while also providing precise speed control.

- Fans and blowers: Shunt motors are often used in fans and blowers, where they provide a constant speed and can operate for long periods of time without overheating.

- Pumps: Shunt motors are commonly used in pumps, including those used for water and sewage treatment, oil and gas production, and irrigation. They are able to provide the high torque required to move large volumes of fluid.

- Conveyors: Shunt motors are often used in conveyor systems, where they provide the precise speed control required for moving materials along a production line